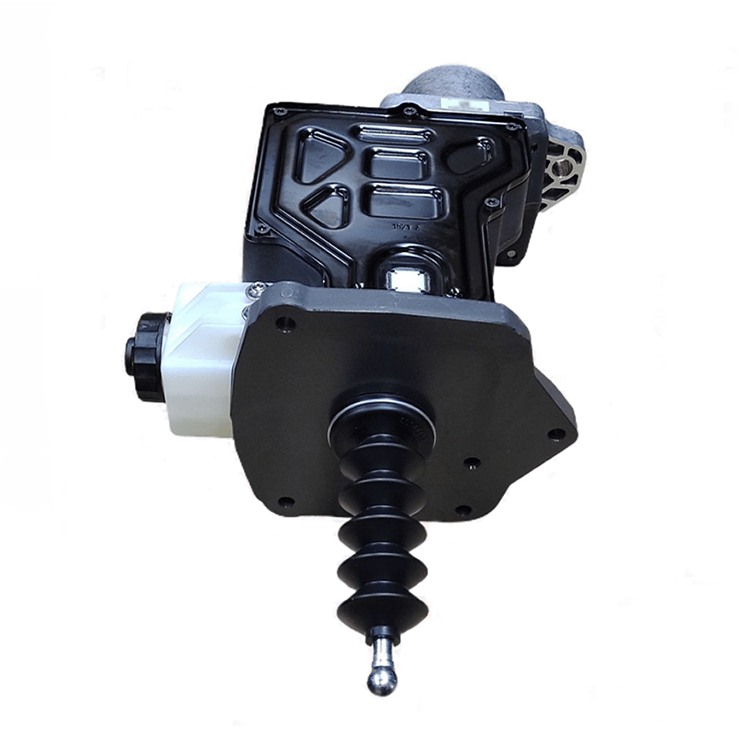

The clutch servo S2CP10087A, a high-performance hydraulic pump designed specifically for SCANIA P-G-R-T models. This robust unit features a distinctive yellow wire and a durable black hose, ensuring both visibility and reliability in demanding environments. With a weight of 9.3 kg, this hydraulic pump is engineered to deliver exceptional power and efficiency, making it an essential component for optimal vehicle performance.

Clutch Servo

Product Description

The clutch servo S2CP10087A utilizes advanced hydraulic technology to assist with clutch actuation, effectively reducing the effort required by the driver. This enables smoother gear transitions, less driver fatigue, and enhanced control over the vehicle. Designed for SCANIA P-G-R-T models, it is a direct replacement part that ensures optimal performance across a wide range of temperatures and demanding work environments.

Product Parameter

|

OEM Number |

S2CP10087A |

|

Applicable Models |

SCANIA P-G-R-T |

|

Carton Dimensions |

|

|

Carton Weight |

9.3kg |

Product Features

Compact Design for Easy Integration: The clutch servo is designed to fit seamlessly into vehicles with limited space, offering powerful performance without occupying unnecessary room.

Optimized Hydraulic Fluid Efficiency: With reduced fluid consumption, this clutch servo lowers operating costs and minimizes maintenance by enhancing the hydraulic system's efficiency.

High Load-Bearing Capacity: Built to endure high-torque conditions, the clutch servo is ideal for heavy-duty trucks, ensuring reliable performance under stress.

Maintenance of Clutch Servo S2CP10087A

1. Check for Leaks: Inspect for hydraulic fluid leaks around the servo and connections. Leaks can affect performance and lead to failure if ignored.

2. Monitor Hydraulic Fluid Levels: Ensure the hydraulic fluid is at the recommended level to maintain clutch operation. Low or overfilled fluid can cause issues.

3. Lubricate Moving Parts: Regularly lubricate the moving parts of the clutch servo to prevent wear. Use the correct lubricants as per manufacturer’s guidelines.

4. Bleed the System: Remove air from the hydraulic system by bleeding it, especially if you notice inconsistent clutch engagement.

5. Check Hydraulic Pressure: Ensure the hydraulic pressure is within the recommended range to avoid faulty clutch operation.

6. Inspect for Contamination: Keep the hydraulic fluid clean and replace it if it appears contaminated with dirt or moisture.

7. Examine Hydraulic Lines: Inspect hydraulic lines and connections for wear or leaks and replace damaged hoses.

8. Inspect Clutch Actuation System: Ensure all components in the clutch actuation system are functioning properly to avoid delays in clutch engagement.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent